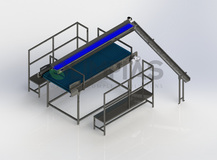

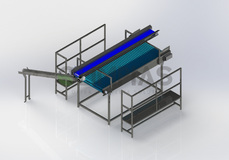

Sorting Table

The sorting - inspection table, is a specially designed machine consisting of rollers, used for fruit processing. It is meant to be a part of a more complex processing line for packaging and/or sorting products. The machine starts running and operates through switches on the electric board. Part movements are automated.

Product transporting speed can be adjusted mechanically or electrically through an Inverter.

The normal work cycle is as follows:

- The products roll onto the inspection table, where the moving – rotating line of rollers rotates them in such a way, allowing the operators to see the whole surface of the fruits.

- Staff performs manual visual control and inspection of the products.

- The products are then transported to the end of the roller section for further processing.

Machine general breakdown:

- The external parts of the machine are constructed from painted structural steel framework and plates, welded and/or bolted.

- The internal parts that come in contact with the product are made of stainless steel.

- The machine’s stands are height adjustable.

- The loading hopper is lined with an elastic material in order to protect the processed products from bruising.

- The diameter of the rollers is Φ48 and the material used is subject to product requirements. Usually used materials are: PVC, Metal, Aluminium Alloy and INOX.